How Dock Scheduling Helps Transportation Directors Eliminate Detention Costs

Modern dock scheduling transforms chaotic facility operations into coordinated systems that reduce detention fees, accelerate invoice processing, and strengthen "shipper of choice" status with preferred carriers.

When weeks-long POD delays block invoice processing, you’re paying twice: once in detention fees, again in delayed cash flow. This guide shows how modern dock scheduling solutions transform these costly operational headaches into competitive advantages that strengthen carrier relationships and reduce total freight spend.

Excessive detention and demurrage charges are silently draining transportation budgets across the industry, with some facilities seeing costs spiral into six-figure monthly bills. The root cause isn’t carrier performance—it’s chaotic dock scheduling that creates driver wait times and operational bottlenecks.

When weeks-long delays getting PODs back from drivers block your invoice processing, you’re essentially paying twice: once in detention fees, again in delayed cash flow.

Modern dock scheduling solutions transform these costly operational headaches into competitive advantages that strengthen carrier relationships and reduce total freight spend.

What is Dock Scheduling and Why Does It Matter?

Dock scheduling is the coordinated system that manages when carriers arrive, which dock doors they use, and how quickly they complete loading or unloading—eliminating the chaos that creates costly driver wait times.

Instead of trucks arriving randomly and sitting idle while you scramble to find available dock space, proper scheduling orchestrates facility access to keep freight moving efficiently.

This directly impacts your three most critical transportation metrics.

- Freight spend improves immediately when detention and demurrage charges disappear—costs that can consume significant portions of your transportation budget when drivers sit waiting.

- Carrier relationships strengthen when your facility becomes known for respecting driver time, giving you leverage in rate negotiations and capacity discussions.

- OTIF performance becomes predictable when you can coordinate dock assignments with pickup and delivery commitments.

In today’s tight freight market, dock scheduling separates preferred “shipper of choice” partners from facilities that carriers avoid. When capacity gets scarce, carriers prioritize loads from shippers who demonstrate operational excellence through efficient facility operations.

Who Needs Dock Scheduling Solutions?

Organizations drowning in detention fees, damaged carrier relationships, and constant “where’s my load” calls need dock scheduling solutions. Different facility types face unique challenges that directly impact transportation costs, operational efficiency, and performance metrics.

Transportation and 3PL Operations

Transportation hubs and 3PL facilities processing dozens of carriers daily face a constant battle between detention costs and carrier satisfaction. When drivers sit for hours waiting for dock assignments, those fees directly impact your freight budget while damaging relationships with key transportation partners.

Carriers remember which facilities create delays—and factor that experience into future rate negotiations or capacity allocation decisions.

Missing PODs from drivers create weeks-long invoice disputes that strain carrier relationships further. Manual coordination failures mean you’re constantly fielding “where’s my driver” calls while carriers question whether to accept future loads.

In tight freight markets, these operational friction points can cost you access to preferred capacity when you need it most.

Manufacturing and Distribution Centers

Manufacturing and distribution centers operating just-in-time (JIT) systems face significant challenges when driver arrivals are unpredictable. Uncertain pickup and delivery times create production scheduling chaos, forcing expensive expedited freight to maintain customer commitments.

When drivers arrive unannounced or outside scheduled windows, detention costs escalate rapidly while dock resources sit idle or become overwhelmed.

Modern dock scheduling transforms this operational uncertainty into predictable throughput. Real-time appointment coordination and automated arrival notifications enable production teams to align manufacturing schedules with actual transportation capacity.

This predictability reduces customer service calls asking “where’s my order,” while eliminating the premium freight costs associated with last-minute schedule changes. Coordinated dock operations support lean manufacturing principles by ensuring materials arrive precisely when needed.

Retail and Grocery Distribution Networks

High-volume retail and grocery distribution centers face unique pressures where dock scheduling chaos directly translates to failed OTIF commitments and customer service breakdowns.

When drivers arrive unannounced or face extended wait times, it creates a ripple effect that delays store deliveries and triggers costly expedited freight to recover service levels.

Poor visibility into yard operations creates operational blind spots that prevent transportation teams from providing accurate delivery windows to store managers or proactively communicating delays.

These facilities also require accelerated invoice processing to maintain healthy cash flow with vendors and suppliers—weeks-long delays getting PODs back from drivers can strain critical vendor relationships and impact payment terms negotiations.

5 Ways Dock Scheduling Transforms Transportation Operations

Transportation directors battle daily operational fires—detention charges consuming freight budgets, damaged carrier relationships limiting capacity access, and operational blind spots preventing proactive planning.

Modern dock scheduling transforms these costly headaches into measurable competitive advantages across five critical areas.

Eliminating Detention Charges: The Hidden Drain on Freight Budgets

Driver wait times at facilities translate directly into detention charges that can consume transportation budgets—costs that compound quickly across multiple facilities and carriers. The problem intensifies when facilities lack real-time visibility into driver arrivals and departures, creating coordination failures that extend wait times unnecessarily.

Real-time scheduling and communication systems eliminate the coordination gaps that keep drivers waiting. Automated check-in processes alert facility staff the moment drivers arrive, while geofenced notifications provide accurate ETAs before trucks even reach your gate.

Coordinated dock assignments ensure drivers move straight to available doors without sitting in queues waiting for space to open up. You’re processing more loads per day while paying significantly less in detention fees, transforming a major cost center into a competitive advantage that strengthens carrier relationships.

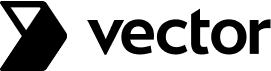

Building “Shipper of Choice” Status: From Damaged Relationships to Preferred Partner

When drivers face excessive wait times and frustrating check-in processes, carriers start declining future loads or charging premium rates to compensate for the operational hassle. During tight freight markets, this becomes a critical competitive disadvantage—carriers prioritize their best customers for available capacity, leaving inefficient facilities scrambling for expensive spot market coverage.

Efficient dock operations transform your facilities into preferred carrier destinations through driver-friendly processes that reduce friction and wait times. SMS-based communication keeps drivers informed of delays or dock changes without requiring phone calls, while predictable appointment windows allow carriers to optimize their daily routes and improve driver utilization.

Streamlined check-in procedures—featuring mobile-based document capture and automated gate access—eliminate the administrative burden that frustrates drivers and delays operations.

These operational improvements translate directly into stronger carrier partnerships and measurable business outcomes. You can track driver satisfaction scores and facility ratings to systematically monitor and improve carrier relationships across your network.

Accelerating Documentation: From Weeks-Long Delays to Instant Processing

Missing or inaccurate documentation triggers costly disputes with carriers and customers, while manual processes pile administrative overhead onto already stretched teams. Carriers prefer fast payment cycles, but weeks-long documentation delays damage these critical relationships.

Digital documentation and automated POD capture eliminate the weeks-long wait for proof of delivery from drivers. Mobile-based digital signatures, real-time photo capture of BOLs, and instant document upload create complete audit trails at the moment of delivery—no more waiting for drivers to mail back paperwork or hunting down missing documents.

You get instant access to shipping documents, accelerating billing cycles from weeks to minutes and improving cash flow immediately. This eliminates the administrative overhead of chasing drivers for missing paperwork or reconciling conflicting documentation that creates disputes.

Your team stops playing phone tag with drivers and starts processing invoices the same day deliveries occur.

Comprehensive digital records support compliance requirements and reduce fraud risk through timestamped, geocoded documentation that’s impossible to manipulate.

Carriers get paid faster, strengthening relationships and improving your “shipper of choice” status. The result is smoother cash flow, eliminated documentation disputes, and transportation partners who prioritize your loads because you pay quickly and efficiently.

Gaining Real-Time Visibility: From Operational Blind Spots to Complete Control

Transportation directors spend their days fielding “where’s my load” calls because they lack real-time visibility into facility operations. Without knowing which trailers are at gates, in queues, or at dock doors, you can’t provide accurate status updates to customers or internal stakeholders.

Modern dock scheduling platforms eliminate these blind spots by providing complete real-time visibility into every trailer’s location and status across your facility network.

Live dashboards show exactly which trailers are in queue, actively loading at dock doors, or departed—complete with timestamps and documentation status. You can see when drivers check in, how long they’ve been waiting, and whether their paperwork is complete, giving you the data needed to provide accurate ETAs to customers and proactively communicate any delays.

This visibility extends beyond the dock to comprehensive yard management. Instead of sending staff to walk the yard looking for specific trailers, you know exactly where every asset is located in real-time.

When customers call asking about their shipment, you can instantly provide specific location updates and realistic delivery windows.

This operational transparency transforms you from a reactive problem-solver to a proactive transportation manager, enabling better decision-making, faster issue resolution, and the exceptional customer service that builds long-term partnerships.

Improving OTIF Performance: From Unpredictable Chaos to Reliable Operations

Unpredictable dock operations create a domino effect of late pickups and deliveries that devastate OTIF scores and strain customer relationships. This operational chaos generates constant “where’s my shipment” calls from frustrated customers and makes it impossible to honor service level agreements consistently.

Modern dock scheduling transforms chaotic operations into predictable, reliable processes that directly improve OTIF performance. Coordinated appointment windows and optimized dock assignments create consistent facility throughput, enabling transportation teams to make accurate delivery commitments with confidence.

Real-time ETA tracking provides the visibility needed to communicate proactively with customers about any exceptions before they impact service levels.

Reduced dwell times and faster trailer turns create measurable improvements in on-time performance throughout your supply chain. Transportation teams can finally maintain service level agreements without constant firefighting, while customers receive the reliable service that strengthens long-term partnerships.

The operational efficiency gains extend far beyond detention savings—you’ll see reduced spot market dependency, better contract carrier utilization, and enhanced transportation planning capabilities.

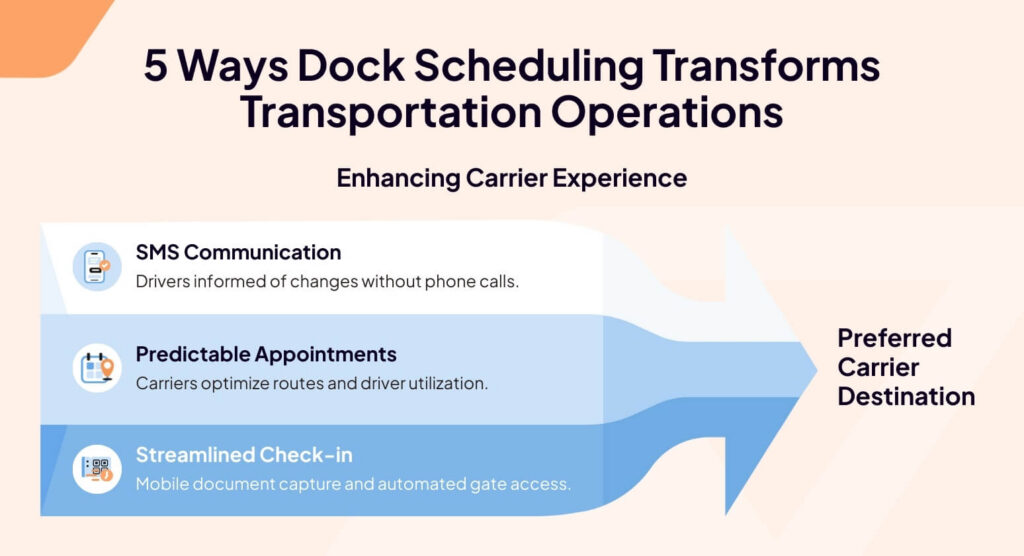

Spreadsheets vs. Modern Dock Scheduling Platforms: What Transportation Teams Lose

Most transportation directors still rely on spreadsheets and manual coordination that unknowingly drive up detention costs and strain carrier relationships. Unlike modern platforms, these manual processes lack four essential capabilities:

- Real-time communication

- Automated documentation

- System integration

- Performance analytics

Manual Processes That Increase Detention Costs

Spreadsheet-based dock scheduling creates a cascade of costly delays that directly impact your detention charges. When drivers call to confirm appointments or report arrival, your team must manually check availability, make phone calls to coordinate dock assignments, and update multiple spreadsheets—adding 15-30 minutes to every interaction.

Last-minute schedule changes become operational nightmares, requiring multiple phone calls and email chains while drivers sit idle in your yard, accumulating detention fees.

Without real-time communication channels, drivers often arrive at the wrong times or at unavailable docks, extending wait times that increase detention charges.

Limited Carrier Communication and Visibility Gaps

Spreadsheets trap transportation teams in a communication vacuum where drivers, dispatchers, and facility staff operate in silos. When carriers can’t coordinate arrival times or receive real-time dock assignments, drivers show up unannounced or at incorrect times, creating bottlenecks that cascade through your entire operation.

You’re left managing detention costs from poor coordination while fielding constant “where’s my load” calls from internal stakeholders and customers.

Without real-time communication channels, you can’t provide accurate ETAs or proactively alert customers about delays. This communication breakdown forces your team into reactive firefighting mode instead of strategic transportation management, ultimately damaging both carrier relationships and customer satisfaction.

Missing Integration Capabilities with Transportation Systems

Spreadsheets live in isolation from your TMS, forcing your team into constant double data entry between transportation systems and facility operations. When load status changes at the dock, you’re manually updating multiple systems instead of triggering automatic notifications to carriers, customers, and internal stakeholders.

This coordination failure means your transportation team operates with stale data—making capacity decisions based on outdated yard status or promising delivery windows without knowing actual facility throughput.

The administrative overhead compounds quickly: staff spend hours reconciling conflicting information between systems, and manual data transfer creates opportunities for errors that impact transportation planning.

You lose the ability to automatically generate detention invoices, update carrier scorecards, or trigger downstream processes when loads complete, turning every status change into a manual task that delays critical transportation decisions.

Inability to Track Key Transportation Metrics

Spreadsheets can’t capture the performance data transportation directors need to manage carrier relationships and optimize operations. You’re missing critical metrics like average dwell times, trailer turn rates, and appointment adherence by carrier—data essential for objective scorecarding and rate negotiations.

Without automated tracking, you can’t identify which carriers consistently perform well or which facilities create the most detention costs. This leaves you making transportation decisions based on gut feel rather than data, unable to reward top-performing carriers or address chronic issues.

Missing analytics means you’re negotiating blind, lacking the performance insights needed to secure better rates or justify capacity allocation decisions during peak seasons.

Essential Features Transportation Leaders Need in Dock Scheduling Software

Transportation directors need dock scheduling software that directly tackles detention fees, strengthens carrier partnerships, and eliminates operational blind spots. The right platform transforms dock operations from a daily cost drain into a competitive advantage that reduces total freight spend while earning “shipper of choice” status with preferred carriers.

Real-Time Carrier Communication and Driver Check-In

SMS-based communication and geofenced mobile check-in eliminate the coordination failures that create driver wait times and trigger detention charges. You can send automated arrival notifications, dock assignments, and departure instructions directly to drivers’ phones without requiring app downloads.

Geofenced check-ins provide accurate ETA tracking as drivers approach your facility, enabling proactive dock preparation and reducing dwell time.

This streamlined communication transforms the driver experience from frustrating delays to efficient facility interactions. Carriers begin preferring your loads over competitors because their drivers spend less time idle and more time generating revenue.

These improved relationships translate directly into better rate negotiations, priority access to capacity during tight freight markets, and carriers accepting your loads even when they’re declining business elsewhere.

Integration with Existing TMS and Transportation Systems

Modern dock scheduling platforms eliminate the data silos that plague transportation operations by integrating directly with your existing TMS through APIs and EDI connections. Instead of manually updating load status across multiple systems, shipment information flows automatically from initial booking through final delivery confirmation.

When a driver checks in at your facility, that status instantly updates in your TMS, triggering downstream processes like customer notifications and invoice preparation.

This seamless data flow means your transportation team gains real-time visibility into every load without switching between systems or chasing down status updates.

You can track trailers from dispatch through facility operations to final delivery—all within your familiar TMS interface, reducing coordination failures that create detention costs.

Automated Documentation and Digital Proof of Delivery

Digital BOLs and automated POD capture eliminate the weeks-long delays transportation directors face when chasing down documentation from drivers.

Instead of waiting for drivers to mail back paper PODs—often lost, damaged, or forgotten—you get instant access to digitally signed delivery confirmations with timestamps and location verification the moment deliveries are completed.

This transforms invoice processing from weeks to minutes, accelerating cash flow and reducing administrative overhead. Your team no longer spends hours tracking down missing paperwork or resolving disputes with carriers over delivery confirmations.

The comprehensive digital audit trail includes driver signatures, delivery photos, and GPS coordinates, creating fraud-proof documentation that eliminates costly billing disputes while supporting compliance requirements for temperature-controlled shipments and regulatory audits.

Performance Analytics for Carrier Scorecarding

Modern dock scheduling platforms provide transportation directors with detailed performance analytics for every carrier interaction. You can track critical metrics like dwell times, turn times, appointment adherence rates, and documentation completion by carrier and by driver.

This data transforms subjective carrier evaluations into objective scorecards backed by concrete performance metrics.

These insights directly support rate negotiations—carriers with consistently faster turn times and better appointment adherence earn preferred status and favorable rates. The analytics also guide capacity allocation decisions, helping you identify which carriers deserve priority loads during peak seasons.

Performance trends reveal operational bottlenecks, enabling you to work collaboratively with carriers to reduce detention costs and improve facility throughput across your entire transportation network.

Mobile-First Driver Experience Without App Requirements

Vector’s SMS-based interface eliminates the biggest friction point in driver adoption—no app downloads required. Drivers simply text a facility code to receive check-in links and real-time updates through their existing messaging app.

This mobile-first approach works across all devices and carriers, ensuring universal accessibility without IT departments managing driver device compatibility.

The system’s automatic translation capabilities communicate with drivers in their preferred language, reducing confusion and processing delays. When drivers can easily navigate check-in procedures in Spanish or other languages, facility throughput increases significantly.

Transportation directors report that this driver-friendly experience directly improves carrier satisfaction scores and makes facilities preferred destinations—critical advantages when competing for capacity in tight freight markets.

Transform Logistics With Smarter Dock Scheduling

Manual dock scheduling processes create the exact problems transportation directors face daily: spiraling detention charges that consume freight budgets, damaged carrier relationships that limit capacity access, and operational blind spots that prevent proactive problem-solving.

Vector’s connected facility platform transforms these costly headaches into competitive advantages:

- Real-time carrier communication and automated check-in eliminate driver wait times and reduce detention costs

- Integrated yard management provides complete visibility into trailer locations and shipment status

- Digital documentation and instant POD capture accelerate invoice processing from weeks to minutes

- Performance analytics enable data-driven carrier scorecarding and relationship management

- Mobile-first driver experience improves carrier satisfaction without app requirements

Discover how Vector can transform your dock operations into a strategic advantage that reduces transportation costs while strengthening carrier partnerships.

Subscribe to stay updated on Vector and logistics trends

" " indicates required fields

Continue reading

Ready to transform your supply chain?

Increase efficiency and productivity. Say goodbye to delays, handwriting errors, and time-intensive manual data entry.